Provide one-stop service of program design, simulation verification, prototype finishing, precision mold processing, MIM manufacturing, testing and inspection,and assembling

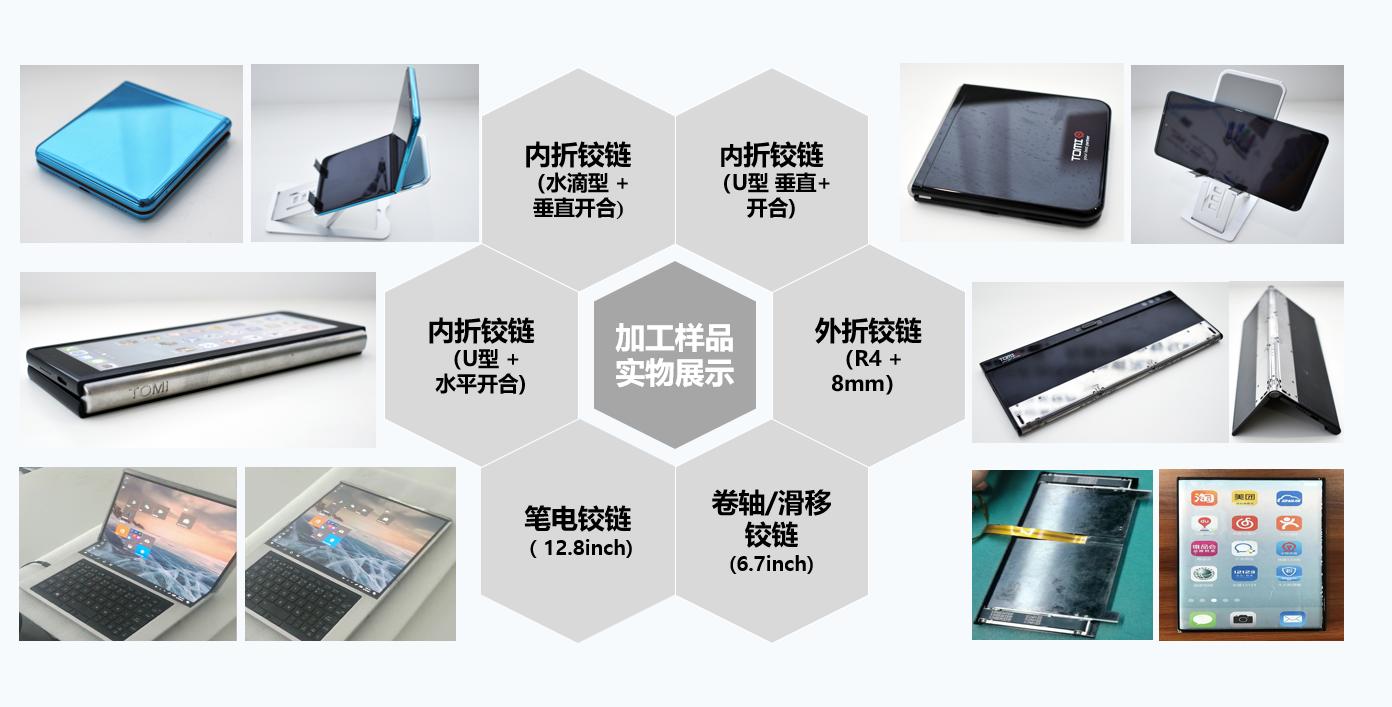

Accumulate rich project experience, has maintained more than 50 models of in-fold / external / multi-fold / reel scheme covering mobile phone and laptop size, and can be adapted to flexible screen

The powerful database of design modules greatly shortens the R&D cycle and is protected by intellectual property rights

MIM parts processing capacity can reach 10 million pieces / month, product accuracy can reach more than 0.02; MIM feeding can reach 20 tons / month

Material applications: low alloy steel, magnetic materials, expansion alloys, nickel/cobalt-based alloys, high-speed steel,tungsten alloys, titanium alloys, etc

There are 2 hinge assembling production lines,and the assembling capacity reaches 100k/M